Inspection and Packaging Systems

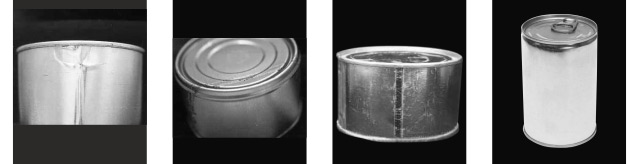

Can Inspection System – VISIOCANEND

Features

- Easy installation on the existing conveyor

- Compact and robust design

- No calibration / adjustment required.

- Zero false rejection rate.

- Up to 7 high resolution cameras.

- Window 10 based computer system and interface

- 17” TFT touchscreen monitor

- IP67 stainless steel enclosure.

- Remote control

- Rejection I/O signals.

- Real time production statistics.

Application

Inspection of all kinds of cans ( Hansa, Dingley,Club, Oval, Round etc) for:

- Pull tab ( position, defects, presence)

- Dents ( minimum 15x15x2mm)

- Patterns and logos

- Holes ( minimum 0.5mm)

- Scratches, Hits , Oxidation

- Label printing, lid printing

- OVC code reading

- Scratches on printing

- Label identification

Double seam quality control system for preserved food cans.

Specification

Speed: 80,000 cans/ hour

Gap: 1 · Ǿ